For a lot of people, hardwood is the undisputed king of flooring choices. Few other materials have the warmth and appeal of a nicely-installed wood floor. What about your high-traffic areas, though? Can you install this type of flooring in halls, entryways, kitchens, and other places where you know conditions are going to be tough on your floors? Yes! If you make the right choices, a wood floor can do a great job standing up to even the busiest of rooms.

The Risks Of Traffic: Different Types Of Damage

At the beginning of your decision-making process, you need to understand the key distinction between the kinds of damage your floors have to resist. General scuffs, wear, and small scratches are all types of finish damage that don’t really make any permanent changes to your flooring.

Dents, gouges, and hard impacts, on the other hand, will cause deep damage that permanently alters the texture of the wood. Holding up to finish damage is (as should be fairly obvious) the job of your floor’s finish layer. Standing up to deep damage depends on the hardness of the wood itself.

In order to survive under high traffic conditions, you need flooring that excels in both categories. A poor finish will have to be reapplied frequently if it can’t handle high traffic. Wood flooring that’s too soft will become uneven and ugly if it suffers too much deep damage.

Natural hardwoods do have an advantage over engineered wood products (see below) in that they can be sanded down to remove deep damage. This is not a cheap or quick maintenance procedure, though, so it pays to start with the densest possible wood.

Separating Finish From Species

In order to hold up in a high-traffic area, you’re going to need wood that delivers the best in terms of both finish and density. Density is largely determined by species (for natural hardwoods) or manufacturing processes (for engineered products).

The quality of your floor’s finish will depend on the nature of the finishing material (stains, polyurethane, acrylic, etc.) and the way in which it’s applied. Since you’re concerned with areas where you know your floors are going to be subjected to lots of wear and tear, buying a prefinished product is strongly recommended.

This does cut down on your aesthetic options (you can’t “fine-tune” the appearance of your floors by adjusting their finish), but the heavy-duty finishes applied by manufacturers deliver much better wear-resistance results than finishes applied after installation.

In most cases, this is because manufacturers’ finishes include a tough layer of aluminum oxide to ward off damage. Both natural and engineered wood flooring can be prefinished.

Top Natural Wood Choices: Exotic Vs. Domestic

The best objective measurement of wood’s hardness is something called the Janka Hardness Scale. It measures the amount of force required to imbed a steel ball into a wooden plank. Note that Janka hardness varies from tree to tree.

And there can be significant differences in density between species and subspecies that are closely related. (Tight-grained sugar maple, for example, is half again as hard as ordinary red maple.) If you want the very toughest natural hardwoods, you need to be prepared to pay for imported lumber.

Many of the densest woods are tropical species, including teak, ebony, mahogany, and Brazilian walnut (also known as Ipe). Of course, these choices can be prohibitively expensive for flooring a high-traffic area, especially if you have a lot of square feet to cover.

Domestic cultivated hardwoods aren’t quite as tough, but they can deliver admirable performance even under challenging conditions. Examples of great domestic hardwoods include the above-mentioned sugar maple, live oak, and walnut.

Engineered Vs. Natural Wood

For flooring a high traffic area, it can be hard to answer the question of which product delivers superior performance, natural wood or engineered wood. As noted above, finish is more important than density when it comes to resisting scuffs and scratches without weight behind them.

Engineered wood typically features exceptional finish quality (especially on premium products). At the same time, though, engineered wood is very vulnerable to deep damage, and you won’t have the option of sanding down a dented wood floor. Engineered wood with a pierced or scarred veneer layer will have to be replaced. If you know that your floors need to stand up to traffic that’s frequent but not particularly intense, engineered wood may be the way to go.

If you make wise choices when picking your lumber, there’s no reason to fear laying down a wood floor in a room that you know is in for lots of traffic. The right materials covered by the right finish can stand up to an astonishing amount of wear and tear. It pays to do your homework and then invest in the toughest products available to you.

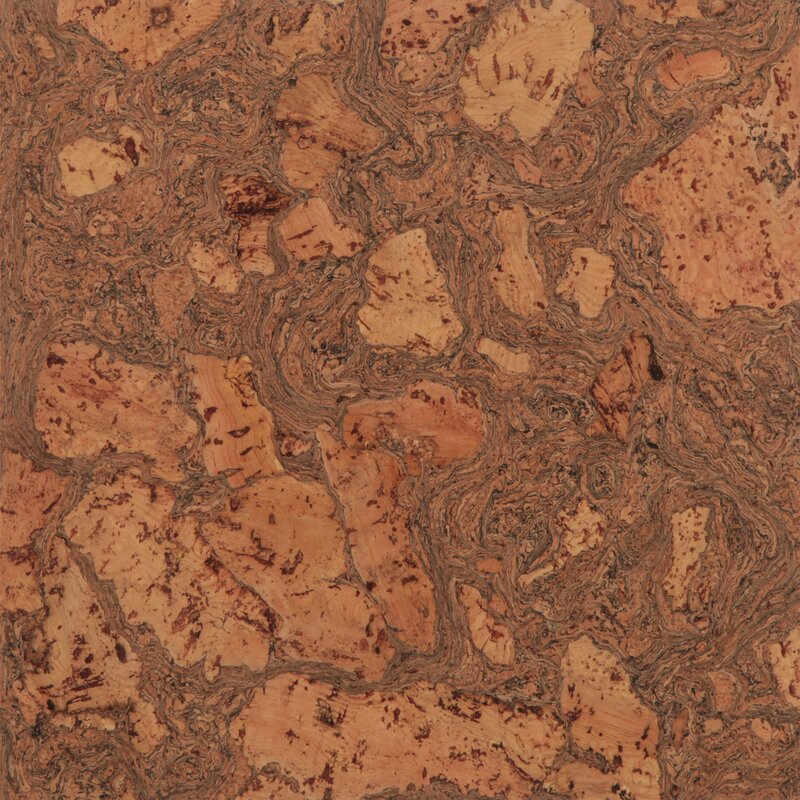

What Is Cork Flooring Made Of?

Buy on Wayfair Cork flooring has become more and more popular in recent years and for many good reasons. While most people are familiar with what cork looks like they’re surprised to find out it’s a natural product. You’re most likely wondering what is cork flooring...

The Advantages Of Hardwood Flooring

Buy on Wayfair Did you know that a hardwood floor can last for multiple decades or even generations? That’s just one of the many advantages of hardwood flooring. Before choosing an option for your floor you’ll want to make sure you check out the other benefits...

The Advantages Of Cork Flooring

Buy on Wayfair When most people think of cork the last thing that comes to mind is flooring. However not, only can it be used on the floor but it has a wide range of benefits. Here are the top advantages of cork flooring that...

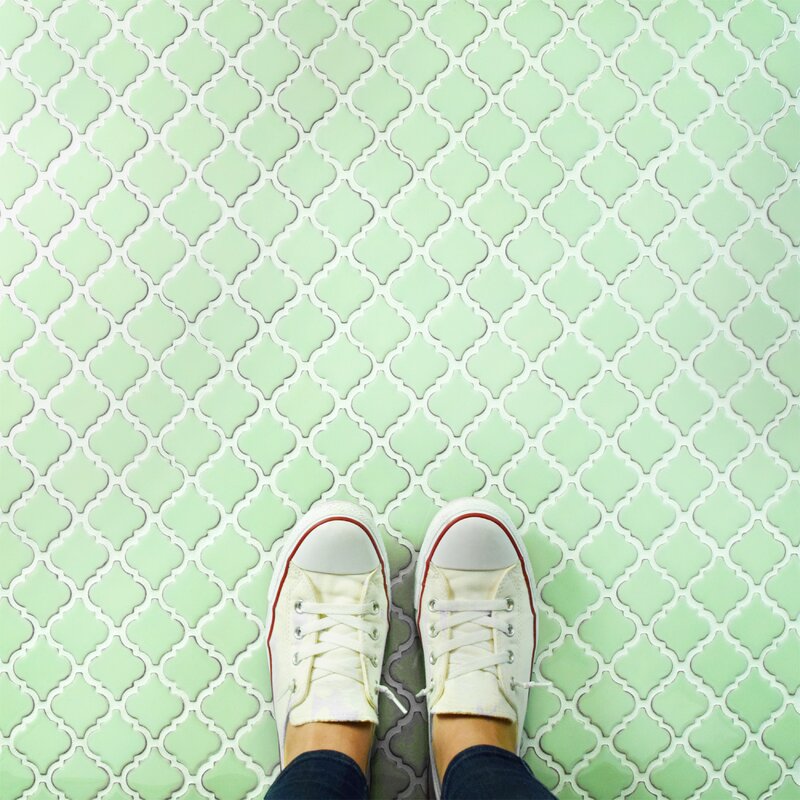

An Intro To The Top Flooring Options

Buy on Wayfair For today’s consumers, there is a wide range of flooring options. Each one offers something different. And in order to choose the right type for your needs, you’ll want to know the basics of each. So here’s an overview of the top varieties you will need...

The Advantages Of Bamboo Flooring

Buy on Wayfair When you want the beauty of real wood but with benefits that are even more consumer and eco-friendly, bamboo is an excellent alternative. And once you read the following advantages of bamboo flooring you’ll quickly understand why. Sustainable Natural...

What Type Of Timber Flooring Is Most Suitable For Your Home?

Buy on Wayfair When it comes to home improvements or new house construction, selecting the right flooring is one of the biggest decisions a person has to make. You have plenty of options to choose from, but one of the most timeless and style-adaptive materials you can...

The Best Ways To Clean Laminate Floors Without Causing Damage

An increasing number of homes today have laminate floors. Laminate is a fairly recent floor surface that is reasonably inexpensive, easy to maintain and extremely versatile. The way in which this type of flooring is composed, including a highly durable top layer,...